Pre-Engineered Buildings

Pre-engineered buildings (PEB’s) are the structures engineered by the design team, fabricated to the exact dimensions at the factory and erected at the site. PEB’s are best-sought designs for structures with longer spans such as industrial sheds, factories, warehouses, community buildings. Some of the key advantages PEB’s have over conventional buildings are that they are economical, reduces the duration of the project, maintains factory controlled quality and durability.

The PEB’s allows the designers to make necessary changes to adapt to the different industry needs like mezzanine floors, canopies, crane systems, trusses, customized lights, turbo vents, etc., This has led to the use of PEB’s for structures like shopping malls, showrooms, schools, hospitals, large-scale manufacturing facilities, etc. As their popularity is increasingly growing, designers and manufacturers are even considering their uses in residential domains as well.

High-Rise Structures

With the cities growing bigger day by day, engineers have felt the need for high-rise structures for various needs of the ballooning populations. High-rise structures are generally used for large commercial and residential spaces. The scarcity of land cover in bigger cities and the advancement in engineering has led to tremendous growth of high rise steel structures.

At SLEW, we design, fabricate and erect the high-rise structures as per codal provisions and customer needs. We also consider strong winds and earthquakes in the location while designing these structures. We guide you through the complete process from engineering to erection with the highest safety standards.

Irrigation Projects

India being an agriculture driven economy, irrigation projects can be described as a lifeline. Construction of irrigation projects deal with huge water forces from the reservoir. At SLEW, we supply structural components like dam gates and gantry girders to withstand the forces and also ensure that they are properly installed.

Light-Gauge Steel Structures

Light-gauge steel or cold form members are made by feeding a thin sheet into a roll forming machine to obtain desired strength. The research on the steel structures has led to the increase in the shift from hot-rolled to cold form steel structures wherever needed. The research revealed that at similar weights, cold-formed steel takes higher loads than hot rolled steel components. The production cost of light gauge steel is low and does not require huge facilities, unlike hot-rolled steel.

Light-gauge steel structures has gained a lot of prominence in the solar module mounting structures as they offer higher strengths at lesser spans. Being weak at the buckling resistance, light gauge steel cannot be used for neither larger spans nor high rise structures. Other applications they can be used include highway barriers, bus shelters, roofing components such as purlins & grits, deck sheets, wall panels, etc.

Industrial Components & Equipment

From functional and safety point of view, few components and equipment require steel fabrication such as boilers, concrete or asphalt mixing plant equipment, blast furnace, hydraulic equipment, equipment for heavy industry applications, liquid filling machines, etc., The process consists of fabricating shells or drums, network of tubes, pipes, mountings and fittings. SLEW has manufactured and installed many such components for various industries.

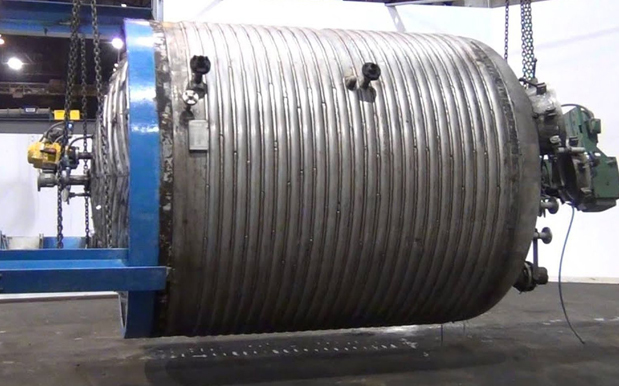

Stainless Steel Reactors & Storage Tanks

Taking into account the everchanging needs of our clients from the pharma industry, we offer premium quality stainless steel (SS) reactors and storage tanks with innovative features and high efficiency. We have a state of the art advance manufacturing facility and competent engineers that provide an unmatched quality SS storage tanks and reactors with long-lasting durability. SLEW offers custom designs, manufacturing, installation, and system integration of corrosion-resistant SS reactors and storage tanks that adhere to international standards.