Applications of Cold Form Steel or Light Guage Steel Structures

Light Guage SteelCold-Formed Steel(CFS), also known as light gauge steel is gaining popularity across sectors due to its ease of handling and structural advantages. CFS currently constitutes a huge market share of around 35% of total steel production. Over time, as awareness of CFS increases, the market share is expected to increase. CFS products can be broadly categorized into structural members and panels. Structural members are designed to meet the desired structural functions in the buildings. On the other hand, panels are used as profile sheets or roof sheets or sometimes for architectural needs.

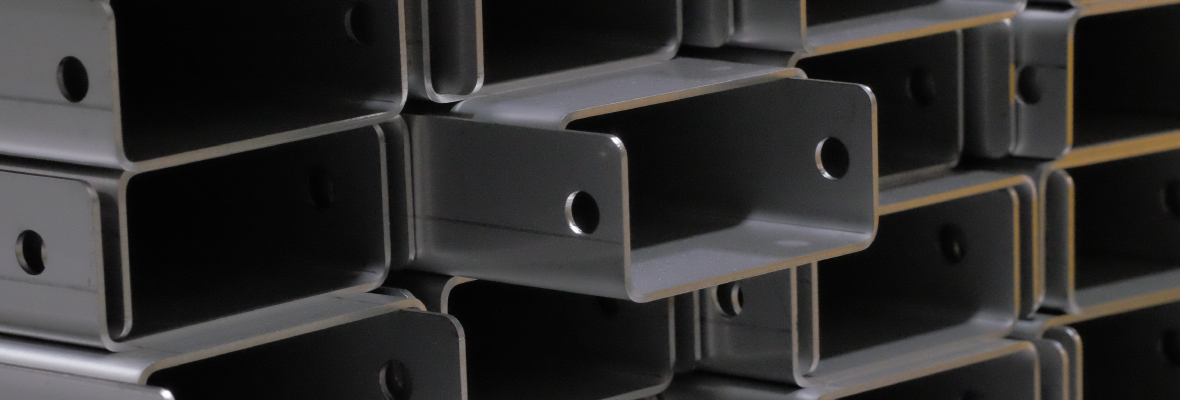

What is Cold-Formed Steel?

CFS members and panels are formed at room temperatures by pressing rolling, bending, stamping and other techniques. They are usually made from steel plates with thickness varying from 2mm to 5mm passing through a series of rollers or press braking to obtain the desired structural shape. This process increases the strength of the steel and provides more flexibility to the designer. The depth of CFS members usually ranges from 50mm to 300mm.

Pros and Cons of Cold-Formed Steel over Hot-Rolled Steel

| Advantages | Disadvantages |

|---|---|

| Lightweight and easy to transport | Not preferred for longer spans |

| High strength and stiffness | Prone to local buckling |

| Easy to handle and install | Not suitable to carry heavy loads |

| Durable | Low fire resistance |

| Desired structural shapes | Not preferred for longer spans |

| Easy to manufacture | |

| Low scrap | |

| Faster construction time |

Despite having such advantages and huge market share in several developed countries, India still lags far behind in catching up with the technology. This blog intends to focus on the applications of CFS in the real world.

Common Applications of Cold-Formed Steel

Structural Members : Closely associated with the construction industry they are often used for entire building structures including roof, floor and wall systems. Based on the functionality, the member shape can be open, closed or built-up sections. Some of such shapes include C-section, I-section (double channel section), Z-section, hat-section, etc. These are usually used as eave struts, purlins, rafters, girts, floor joists, braces etc. CFS is finding wider applications in residential market. It minimizes labour costs since CFS can be cut to required length by the manufacturer itself.

Solar Structures : All the members used in the module mounting structures for the solar panels are made of Cold Formed Steel. With solar structures gaining importance in recent times, the demand and awareness of CFS has also increased. CFS members are cheaper and have the structural capability to withstand higher wind forces. .

Pre-Engineered Buildings : CFS building components almost fill up the entire pre-engineered buildings sector. Members such as purlins, bracings, eave struts, roof sheets, wall panels are made of CFS. This is where considerable CFS members are being used today.

Decks : Roof and floor decks are some of the primary applications of CFS. Decks make use of cellular CFS shapes that reduce deadweight and permit lightweight floors. Such flooring systems can also provide data cable distribution, communications and electrical power as well alongside air conditioning and heating ducts.

Insulated Panels : CFS panels are also utilized to keep out the weather and retain heat within buildings. Pre-insulated CFS panels are now available. These panels are placed as rigid urethanes sandwiched in between steel.

Wall Panels : A wide variety of panel systems are available for walls nowadays. CFS wall panels can be formed, coated and modified according to needs. Often used as structural support for brick veneer and insulation finishing system, exterior wall systems are put together with studs connecting the top and bottom tracks. These types of stud walls system are often used to carry the floor load. They also effectively provide stability for the building. CFS is also used for partitions and interior walls since they provide flexibility depending on the layout of interior spaces as well. They also provide the freedom of relocating and redesigning the structure. Additionally, CFS framing supports duct enclosures, ceilings and shaft walls.

Culverts: These are made of cold-formed corrugated steel pipes. CFS culverts are commonly used for everything from huge bridge structures to simple tunnels under roads and storm sewers. CFS corrugated pipes are installed in a cut form then subsequently covered with fills. Forming an inexpensive and durable bridge option, they are finally topped up with a roadway.

Floor and Roof Trusses : In recent years CFS trusses have gained a significant share of the market. Trusses are normally made from regular C-section studs and/or in other types of proprietary shapes although, similar design flexibilities and span capabilities are provided by CFS trusses. CFS trusses are light in weight and dimensionally stable. Most CFS trusses are pre-engineered. Flexibility in design makes CFS trusses most ideal for industrial, educational and institutional buildings that may be made for residential or commercial structures.

Racks : Most storage specialists and material handling experts rely on CFS racks. These rack systems efficiently store and retrieve everything from heavy steel bars to food items. Newer designs of CFS rack systems are extremely huge and can fill the entire building as well. They have stacker cranes which can rise as high as 30 meters/100 feet.

Few other real-time applications

Highway barriers Doors and Windows

Urban bus stops Guard rails

Utility poles Automobile bodies

Grain bins Furniture and many more.

The applications of Cold-Formed Steel are endless as it can be formed to any shape you desire with the strength, stiffness and durability. With a bucket of advantages and low infrastructure needed to roll-form, CFS has a long way to go!